Vergusstechnik

Punktgenaues Dosieren hochwertiger Vergussmassen direkt am Bauteil.

Während Verfahren wie das Conformal Coating (Beschichten) aus der Leiterplattenindustrie bestens bekannt waren, gewann der Vollverguss für LED-Anwendungen erst in den letzten 10 Jahren an Bedeutung. Da jeder Kunststoff (wie auch beim Conformal Coating) eine gewisse Wasseraufnahme besitzt und die Feuchtigkeit ab einem Punkt durchlässt, gab es schnell Einsatzbereiche, die eine robustere Schutzart benötigten. Hierfür ist der Teil- oder Vollverguss ideal.

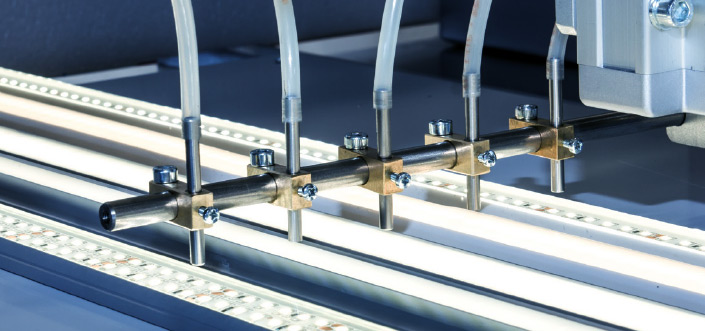

Beim Verguss wird mit Hilfe einer automatischen Dosier- und Mischanlage ein (in der Regel) 2-komponentiges Harzgemisch gefördert, homogenisiert und in das Bauteil gegossen. Das Polyol (A-Komponente) und das Isocyanat (B-Komponente) sind extrem feuchtigkeitsanfällig im ungemischten Zustand, weshalb eine automatisierte Dosierung zwingend erforderlich ist. Ein Verguss von Hand im klarsichtigen LED-Bereich ist kein zuverlässiges Serienverfahren. In den Maschinen sind die Materialien zu jeder Zeit vor Feuchtigkeit und anderen Umwelteinflüssen geschützt. Des weiteren ist eine perfekte Homogenisierung gewährleistet, um Schlieren, Blasen und andere Effekte zu vermeiden.

Der Verguss ist in verschiedenen Härten, Viskositäten und Farben einstellbar, sodass auch Bodenapplikationen möglich sind. Die ,,translucente” (homogene/opake) Vergussschicht hat sich als ,,Top Coat” (oberste Schicht) etabliert. Sie sorgt für eine homogene Lichtaustrittsfläche, ohne LED-Punkte. Des weiteren sorgt sie für einen haptisch anspruchsvollen Leuchtenabschluss, und weist eine höhere Wasserbeständigkeit auf.

Leuchtenkörper:

Als ,,Füllkörper” sind viele unterschiedliche Materialien nutzbar. Getrieben durch andere LED-Anwendungen nimmt der Verguss von Aluminiumprofilen eine große Rolle ein. Aber auch Edelstahl oder haftungsoptimierte Kunststoffe werden genutzt. Bei der Auswahl des Körpers ist sehr entscheidend wie die späteren Umwelteinflüsse aussehen, wie viel Wärme entsteht und abgeleitet werden muss, und wie die unterschiedlichen Ausdehnungskoeffizienten zueinander arbeiten.

Eloxiertes Aluminiumprofil

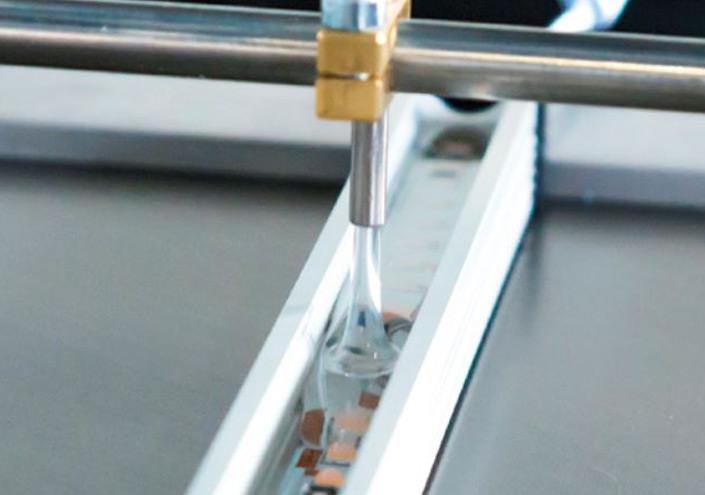

Im Bild zu sehen ist ein eloxiertes Aluminiumprofil, mit eingeklebter flexibler LED-Platine und einem mehrschichtigen Polyurethan-Verguss. Schutzklasse IP67.

Flexibles vorgegossenes Polyurethan-Gehäuse

Im Bild zu sehen ist ein flexibles vorgegossenes Polyurethan-Gehäuse. Dieses wird ebenfalls mit der Vergussanlage produziert, entformt und eingelagert. Der Vorteil sind identische Rahmen- wie Innenvergussmaterialien. Es entsteht eine völlig flexible Lichtlinie.

Formenbaumaterial

Im Bild zu sehen ist ein (grünes) Formenbaumaterial, in welches weißes Polyurethan gefüllt wird. Hieraus kann z.B. ein U-Profil entstehen, das als späterer Träger für den LED-Stripe dient.

Eigenes Extrusionsmaterial

Alternativ hierzu haben wir ein eigenes Extrusionsmaterial, welches die Herstellung flexibler Klappprofile auf Rolle ermöglicht. Wir können Ihnen dieses beistellen, lesen Sie hier mehr dazu.